Description

| material | SS-CrNi |

|---|---|

| packing unit | 1 roll |

| width | 16,0 mm – 5⁄8″ |

| thickness | 0,75 mm – .030″ |

| length | 50 m |

| colour | grey |

| weight | 5.0 kg |

50 m/roll

full round edges

SS-CrNi

width: 16,0 mm – 5⁄8″

thickness: 0,75 mm – .030″

colour of dispenser: grey

weight: 5,0 kg

| material | SS-CrNi |

|---|---|

| packing unit | 1 roll |

| width | 16,0 mm – 5⁄8″ |

| thickness | 0,75 mm – .030″ |

| length | 50 m |

| colour | grey |

| weight | 5.0 kg |

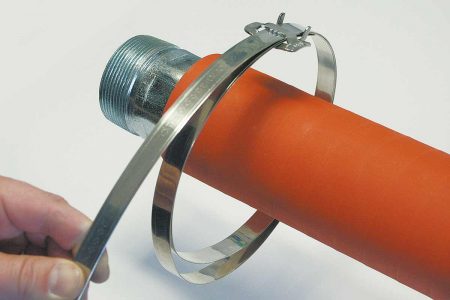

Pull buckle on band, ears pointing towards end of band. Form clamp, holding band on band, then push buckle back over the doubled band, bending the end approx. 1″ under buckle.

Pull buckle on band, ears pointing towards end of band. Form clamp, holding band on band, then push buckle back over the doubled band, bending the end approx. 1″ under buckle.

For heavy duty jobs double wrap band.

For heavy duty jobs double wrap band.

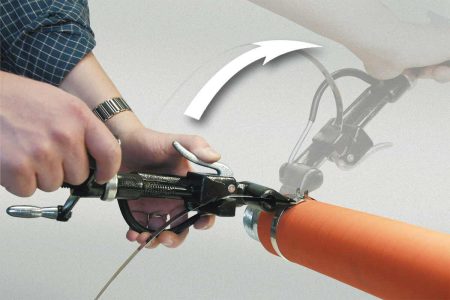

Place band in tool, push down on gripper with thumb, tension clamp by turning handle. Maximum tension is reached when band stops moving through buckle.

Place band in tool, push down on gripper with thumb, tension clamp by turning handle. Maximum tension is reached when band stops moving through buckle.

When required tension has been applied, roll tool over buckle, at the same time reversing handle carefully approx. half turn to avoid breakage. There is no loss of tension, if handle is not reversed too much.

Pull on cutter lever, band is cut off to correct length.

Pull on cutter lever, band is cut off to correct length.

Hold stub of band with thumb, hammer it flat over bridge of buckle, complete clamp by hammering

ears over stub.

Hold stub of band with thumb, hammer it flat over bridge of buckle, complete clamp by hammering

ears over stub.